Current Projects

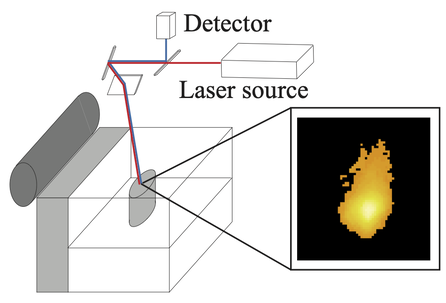

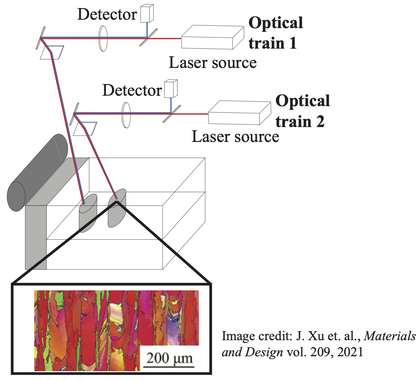

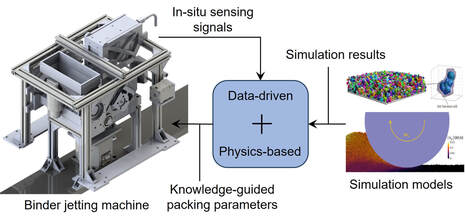

Close-Loop Control of Metal Binder Jetting Additive ManufacturingDespite the growth of metal binder jetting (MBJ) due to its scalability and cost-effectiveness, the high cost of powder impedes its broader industrial adoption. In this project, we investigate the use of cost-efficient water-atomized powder (WAP) as an alternative to the more expensive gas-atomized powder (GAP). We focus on the potential of powder surface topography and ultrasonic signals as indicators for MBJ powder bed density, with the aim of implementing closed-loop control.

|

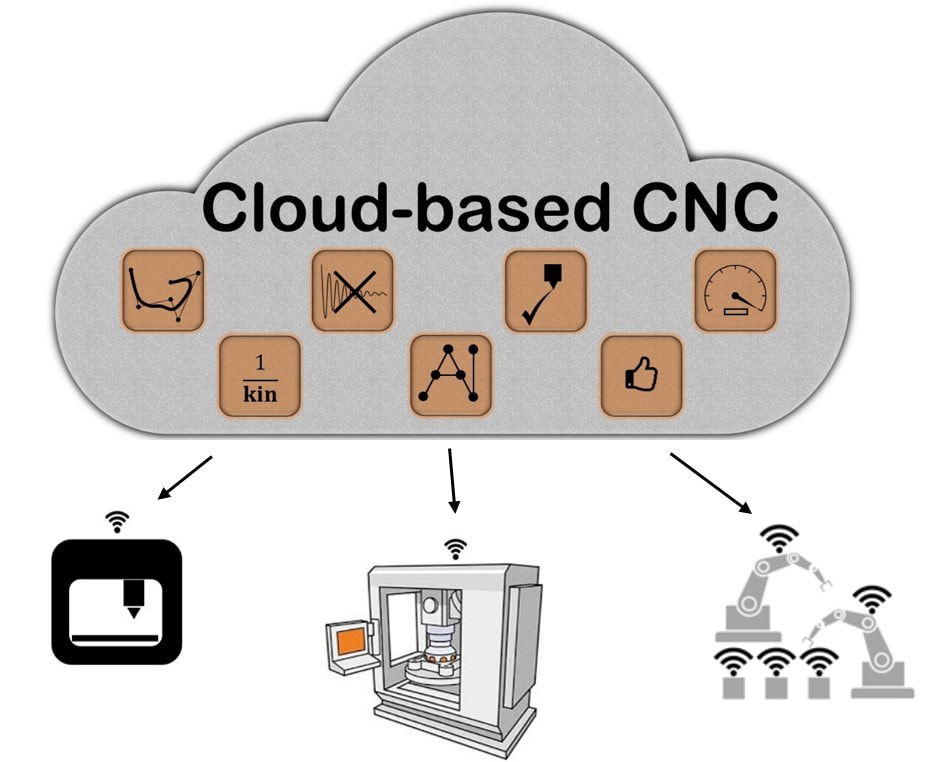

Towards Control as a Service via Cloud-based CNCControl as a Service (CaaS) is an emerging paradigm where low-level control (e.g., computer numeric control - CNC) of a machine is moved from a local computer on the machine to a remote computer in the cloud, from where it is provided to the machine as an on-demand service over the internet. A machine with access to CaaS can, therefore, leverage the vast computational resources available in the cloud to run advanced control algorithms that boost its performance at low cost. CaaS also facilitates easy upgrades to the control system of a machine and enables it to become more “intelligent” by leveraging data sharing and analytics. This project tackles challenges of safety and reliability of cloud-based CNC using strategic redundancy and machine learning.

This project is sponsored by the National Science Foundation's Grant # 1931950 and Cisco

|

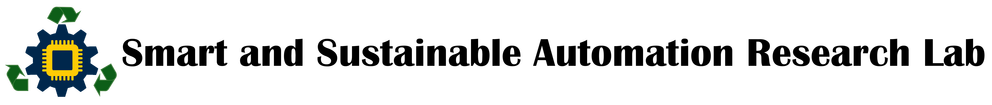

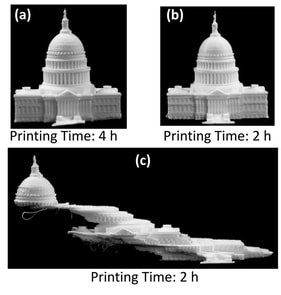

Boosting the Speed and Accuracy of Vibration-prone Manufacturing Machines at Low Cost through SoftwareMost manufacturing machines vibrate as they move, due to weaknesses in their mechanical structures. The resultant motion-induced vibration adversely affects the accuracy and speed of the manufacturing machines, thus degrading the quality and productivity of the associated manufacturing processes. This project investigates a filtered basis functions approach for compensating the vibration and servo errors of manufacturing machines via software. The benefit of using software is that it does not add to the weight, size or hardware cost of the machine. An interesting application of this approach is desktop 3D printers, because it boosts their speed and precision at low cost. However, software vibration compensation also applies to high-end manufacturing machines.

This project is sponsored by the National Science Foundation's Grant # 1825133, # 2032814, # 2054715 and the Michigan Economic Development Corporation

|

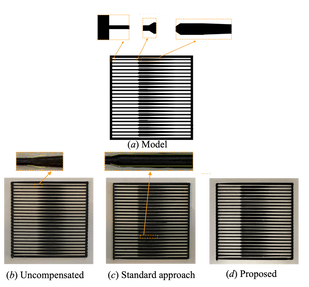

Deposition Control for Material Extrusion Additive ManufacturingHigh-quality material extrusion requires accurate synchronization between the dynamically dissimilar systems: the fast positioning and slow extrusion system. To improve the deposition accuracy in material extrusion additive manufacturing, this project aims at modeling the nonlinear extrusion dynamics, and developing model-based control strategies by efficiently using both the position and extrusion system.

|

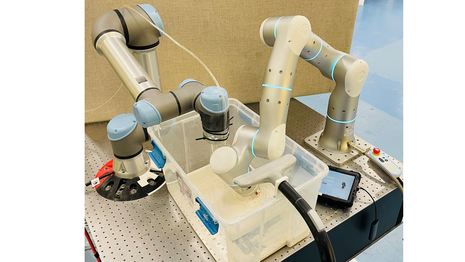

Robotic Depowdering for Metal Binder Jetting Additive ManufacturingRobotic depowdering is a technique used in metal binder jetting additive manufacturing to remove excess powder from printed metal parts using robotic arms and automated systems. Robotic depowdering offers several advantages in metal binder jetting additive manufacturing. It provides a consistent and repeatable depowdering process, minimizing human error and variability. It also improves efficiency by automating the depowdering step, allowing for faster processing times. Additionally, robotic systems can be designed to handle delicate parts and complex geometries, ensuring gentle and precise depowdering.

|

Past Projects

This project is sponsored by the National Science Foundation's Grant # 1562297 and #1855354

|

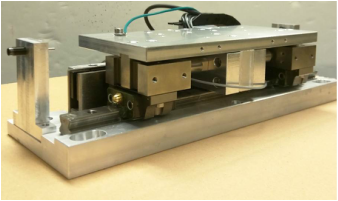

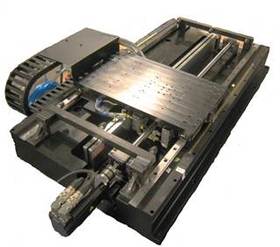

Improvement of Speed and Precision of Low-cost NanopositionersNanopositioners are mechanical devices used for precise positioning in a wide range of nanotech processes. Rolling bearings enable low-cost nanopositioning but suffer from reduced speed and precision due to friction. This project explores two approaches to mitigate friction: (1) vibration assisted nanopositioning, i.e., the use of high-frequency vibration, combined with active vibration control; and (2) friction isolator, i.e., the use of a compliant joint between rolling bearings and nanopositioning stage. Both approaches have demonstrated significant improvements in posiitioning speed and precision while maintaining the cost-effectiveness of rolling bearings.

|

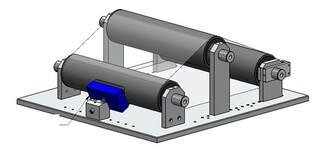

Improvement of Speed and Precision of Roll-to-roll ManufacturingHigh precision roll-to-roll processes are believed to be one of the most promising technologies for manufacturing flexible and large-area thin film electronics. However, broadband frictional disturbances caused by the guiding ball bearings affect the precision of the processing roller in the roll-to-roll system, severely hampering the quality of the manufactured products. This project extends the friction isolator approach for nanopositions to mitigate frictional disturbances in roll-to-roll manufacturing. Thus, it enables high speed, high precision roll-to-roll manufacturing at low cost.

This project is sponsored by the National Science Foundation's Grant #1855354 and the Korea Institute for Machinery and Materials (KIMM)

|

This project is sponsored by the National Science Foundation's CAREER Award # 1350202

|

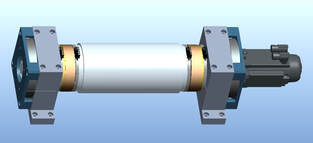

Dynamically Adaptive Feed Drives for High Performance and Energy Efficient ManufacturingLinear motors are used for fast and accurate motion delivery in a wide range of precision manufacturing machines. They however consume a lot of energy and generate a lot of heat in the process. In this project, we explore a mechatronic design concept where the electro-mechanical structure of linear motor driven machines is designed much like the power train of hybrid electric vehicles; i.e., their structure is designed to intelligently vary in real-time as a function of the manufacturing operation being performed, so as to simultaneously achieve high performance and improved energy efficiency.

|

Low-cost and Energy-efficient Reduction of Vibrations in Ultra-precision Manufacturing MachinesUltra-precision manufacturing (UPM) machines (e.g. ultra-precision machine tools, wafer scanners and micro CMMs) are designed to fabricate and measure complex parts having micrometer-level features and nanometer-level surface finishes. They are often plagued by a combination of ground vibrations and residual vibrations which occur while executing motion commands. We are carrying out a model-based study of the dynamics of passively isolated UPM machines to determine ways of reducing vibrations via design-level mechatronic optimization – without resorting to active vibration control – thus reducing costs and energy consumption

|

This project is sponsored by the National Science Foundation's Grant # 1232915

|

Enabling Performance and Fuel Efficiency Improvements in Vehicles by Developing Dynamic Models for Electric Power Assist Steering SystemsElectric power assist steering (EPAS) systems deliver improved fuel efficiency and flexibility to modern-day automobiles. However, they are plagued by a so-called "sticky feel" which adversely affects their performance. This project, funded by Ford Motor Company, seeks to develop dynamic models that provide insights on how to design and control EPAS to minimize the sticky feel thus enhancing the performance and wide-spread use of EPAS.

|

Enabling Improvements in Fuel Efficiency via Modeling and Design Optimization of GDI ActuatorsThe objective of this project is to improve fuel injector performance in Gasoline Direct Injection (GDI) engines via multi-physics modeling that encompasses electro-magnetics, collision dynamics, and fluid dynamics. Compared to the traditional port fuel injection systems in IC engines, GDI provides major advantages such as increased fuel efficiency, higher power output, and lower emission levels. This project is funded by the Ford Motor Company and MCubed 2.0. It is performed in collaboration with the Precision Systems Design Lab

|

Low-Resource Settings

Pathways to Sustainable Manufacturing in

|